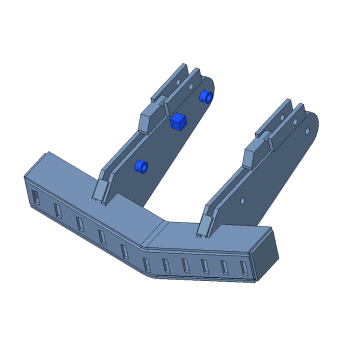

Scarifier

Motor Grader is a classical machine in the full range of construction equipments. It is an important equipment for Road construction and New Railway line laying works. It is also used in Canal works. Reliability of Motor grader is a paramount important as a fleet of Road construction equipments depend on the availability of Motor Grader in working condition. The Brake down in Motor grader leads to the fleet of equipments coming to a grinding halt, which are all depend on the proper functioning of Motor Grader. Hence ensuring the reliability of the structural parts developed for Motor Grader is very important. RSB has developed the critical structural parts of the Motor Grader such as Main Frames, Draw bar which is also known as A- Frame, Scarifier and Saddle etc.

RSB has capabilities to manufacture Scarifier(14T) since 1998. RSB is in the field of manufacture of Loader Structures such as Loader Arms, Front and Rear Frames of different categories of Wheel Loaders including Mining category Wheel Loaders. RSB has catered to the full range of structural parts for Back-hoe Loader manufacturers. It has the capability to develop Motor Grader parts such as Rear frames, Draw Bar / A Frames, Grader Boom, Scarifier and Mould Board etc.

RSB’s inhouse develop and manufacturing facilities (under one roof) for, laser cutting oxy cutting, plasma cutting, bending, rolling, robotic welding and machining provides better product integrity with following specification.

Product Features

Product Variants

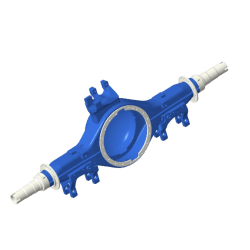

Live Axle Beam/Housing

RSB has developed capabilities to design and manufacturing live axle beam (housing) since 2008. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding, robotic welding and machining provides better product integrity with following specification.

Dummy Axle beam

RSB has capabilities to design and manufacturing live axle beam (housing) since 2004. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding and robotic welding provides better product integrity with following specification. By end of 2022, RSB has sold 1 million axle to India OEMs.

Lift axle Beam

RSB has developed lift axle beam (tubular drop) for dual tyre lift axle for multi axle rigid trucks and haulage tipper application. RSB manufacture the drop tube through cold bending with roller technology (sole manufacturer in India) with controlled CTQ parameters (minimal thinning, ovality, residual stress, straightness). We supply lift axle beam to major OEMs in India.

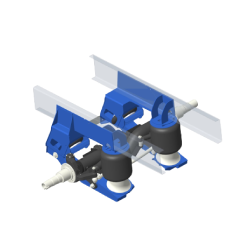

Steerable Lift axle

RSB Transmission has done strategic alliance (Technical collaboration) with Reyco Granning LLC, USA for primary air suspension & auxiliary (lift) axle for multi axle rigid trucks, tipper, tractor and bus application. Reyco Granning LLC is having 90 years of experience in designing and manufacturing suspension solutions.

12,5T -self steerable lift axle & suspension is a trailing arm type air ride suspension with straight or drop axle for tag / pusher positions for rigid trucks and haulage tipper application.

Product specification

- Model: 14T

- Component Weight in Kg: 194 Kg