Propeller Shaft

RSB is the most reliable Propeller Shaft supplier in automobile industry. Our Propeller Shafts are tried and tested by the OEMs over the past many years. We Design, Develop & Validate these Propeller Shafts by using latest technologies. Our Product range covers all requirements and different varieties of Propeller shafts technically perfected for many applications.

RSB Propeller Shafts are designed for Optimum weight for the required Torque Transfer. RSB has also developed & tested Propeller shaft made of alternate light weight material as well as with high strength material. RSB Propeller Shaft division holds the highest Quality certification - Deming Prize & TPM Excellence award, and Other Certifications like IATF / TS 16949, ISO 14000&OHSAS.

Product Features

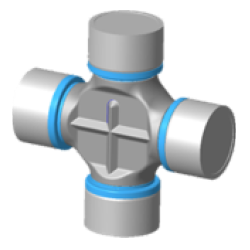

Universal Joint

- Robust design for higher load capability

- Improved sealing through multi lip seals

- Polyamide thrust washer for better thrust load capability and improved life of cross & bearing cup

- Environment friendly synthetic lithium-based grease for longer life

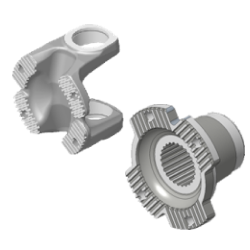

Sliding Joint

- Involute profile spline guarantees optimized performance

- Polyamide coated sliding joint outer and inner surfaces for smooth Sliding & better wear resistance property.

- Double lip seal with metallic dust cover for improved sealing

- Standard sliding length ranges from 70mm to 180 mm

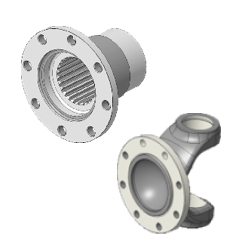

Mounting Yoke

- SAE-Mounting flanges

- 4-hole mounting flange with x-serration (ISO 12667/ ISO8667)

- High torque to weight ratio

- Optimum weight of the forgings

- Higher deflection angle (up to 44°) for inter axle shaft applications available

The X-serrated flange is the preferred flange because of its Techno-Commercial advantages including the following:

- International standardization (ISO)

- Fewer variants

- Form fitting, highest torque transfer efficiency

- Clearly defined mounting position

- Less time required for assembly

- Positive drive

- Simplified bolting

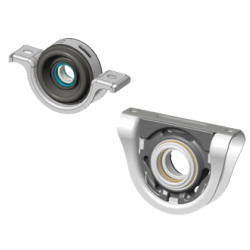

Center Bearing Assembly

- Robust center bearing kit

- Honeycomb design rubber housing available for

1. Dampening and isolation

2. Cushioning axial movements

3. Cushioning angular movements and positions - Deep groove ball bearings with 2RSR (double sealing) and service free grease to keep out dirt and moisture

- Center bearing dust cover provided to prevent water and dust from entering

Product Variants

For propeller shaft assembly to various transmissions and axle assemblies, variants of mounting flanges are available to match gear box and axle mounting flanges.

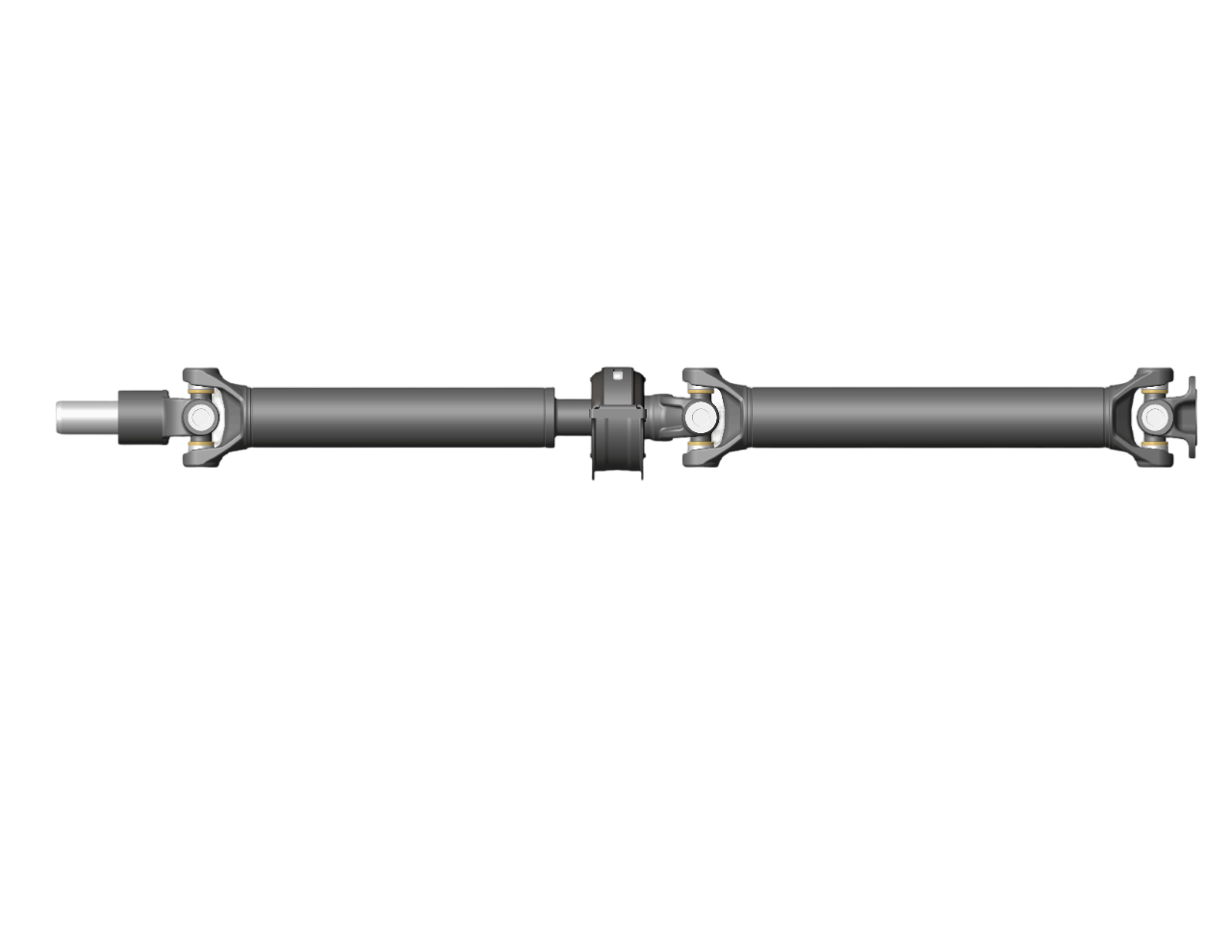

Variant A100

Coupling shaft with centre bearing assembly.

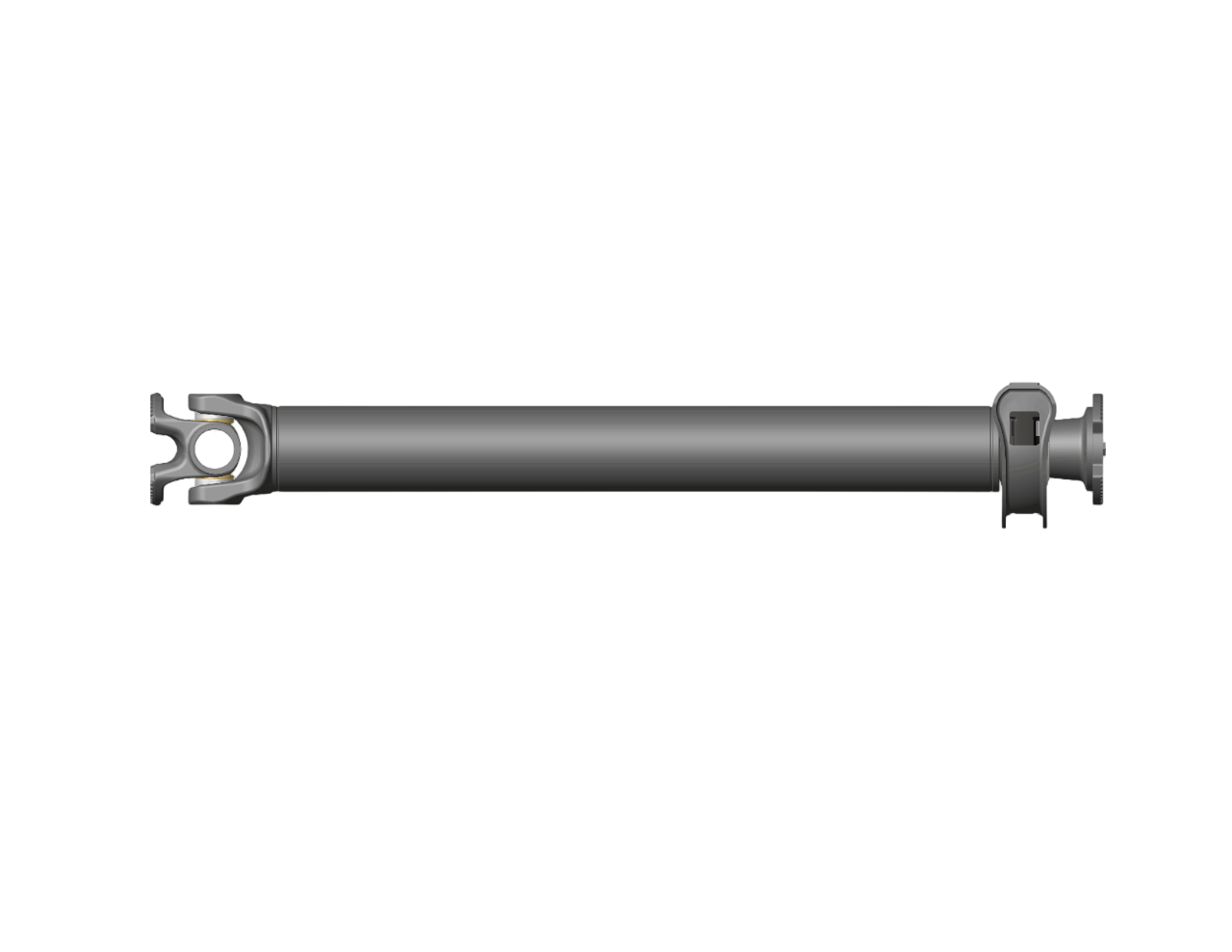

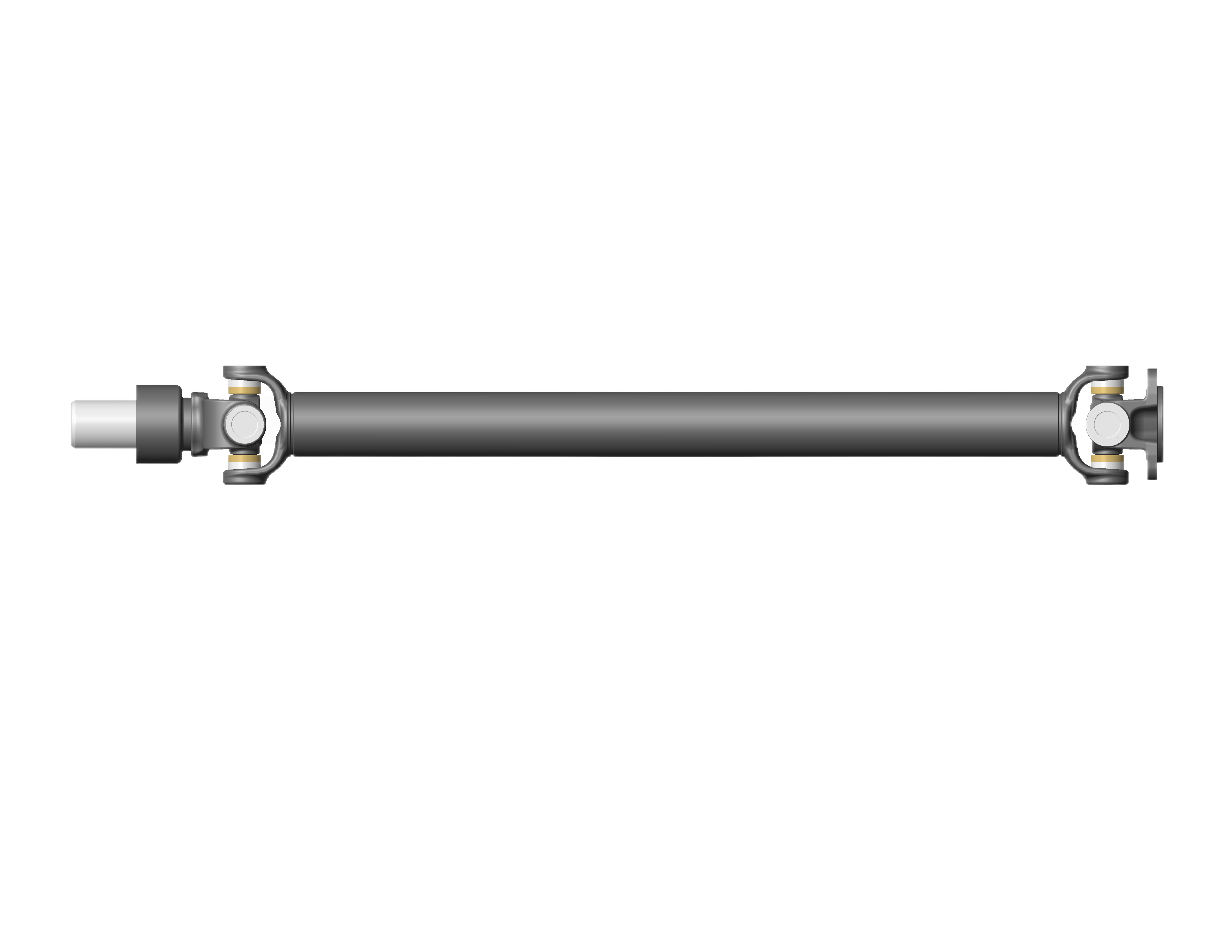

Variant A120

Drive shaft with length compensation.

Variant A140

Short coupled drive shaft with length compensation.

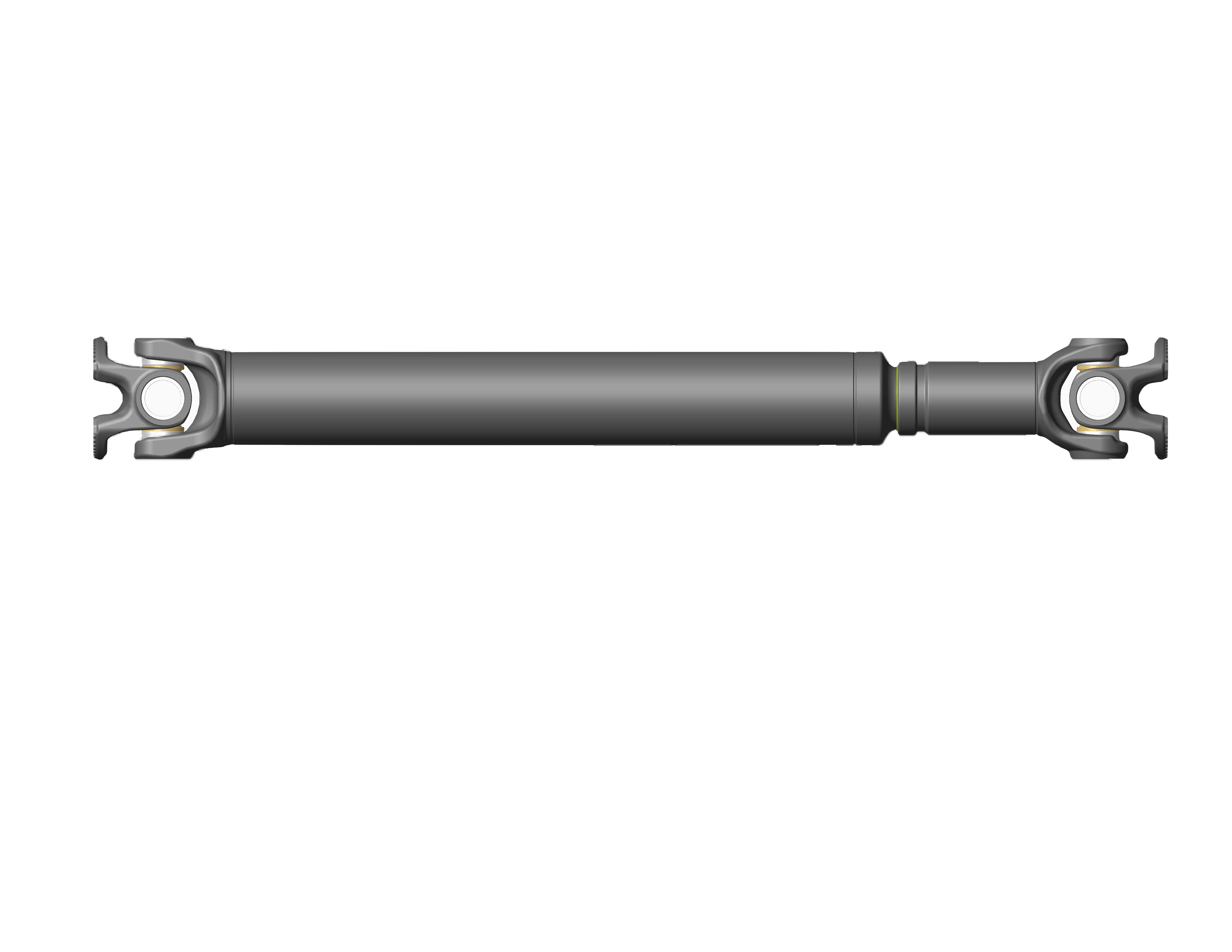

Variant A160

Unitized drive shaft with length compensation & center bearing assembly.

Variant A180

Unitized drive shaft with front length compensation & center bearing assembly.

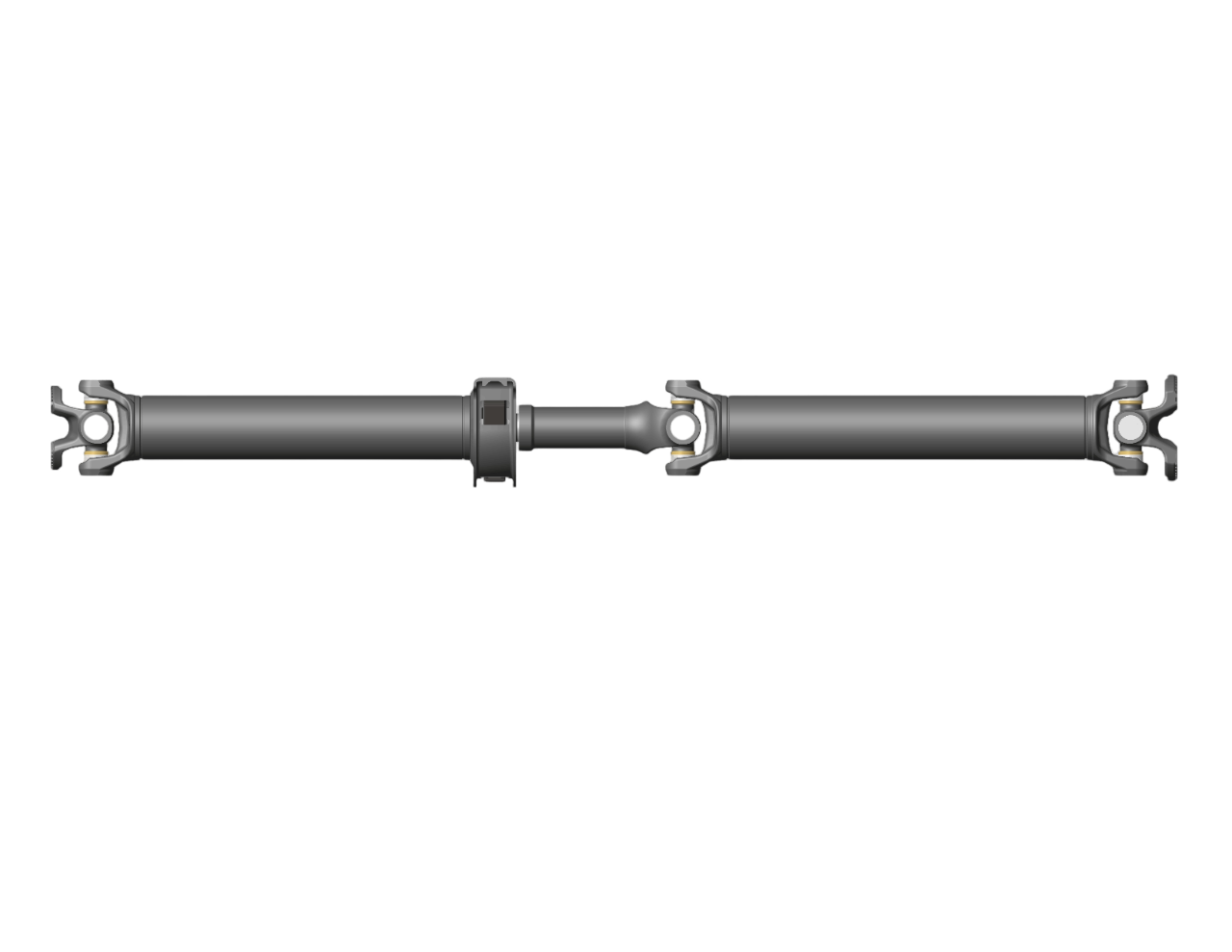

Variant A200

Drive shaft assembly with front length compensation.

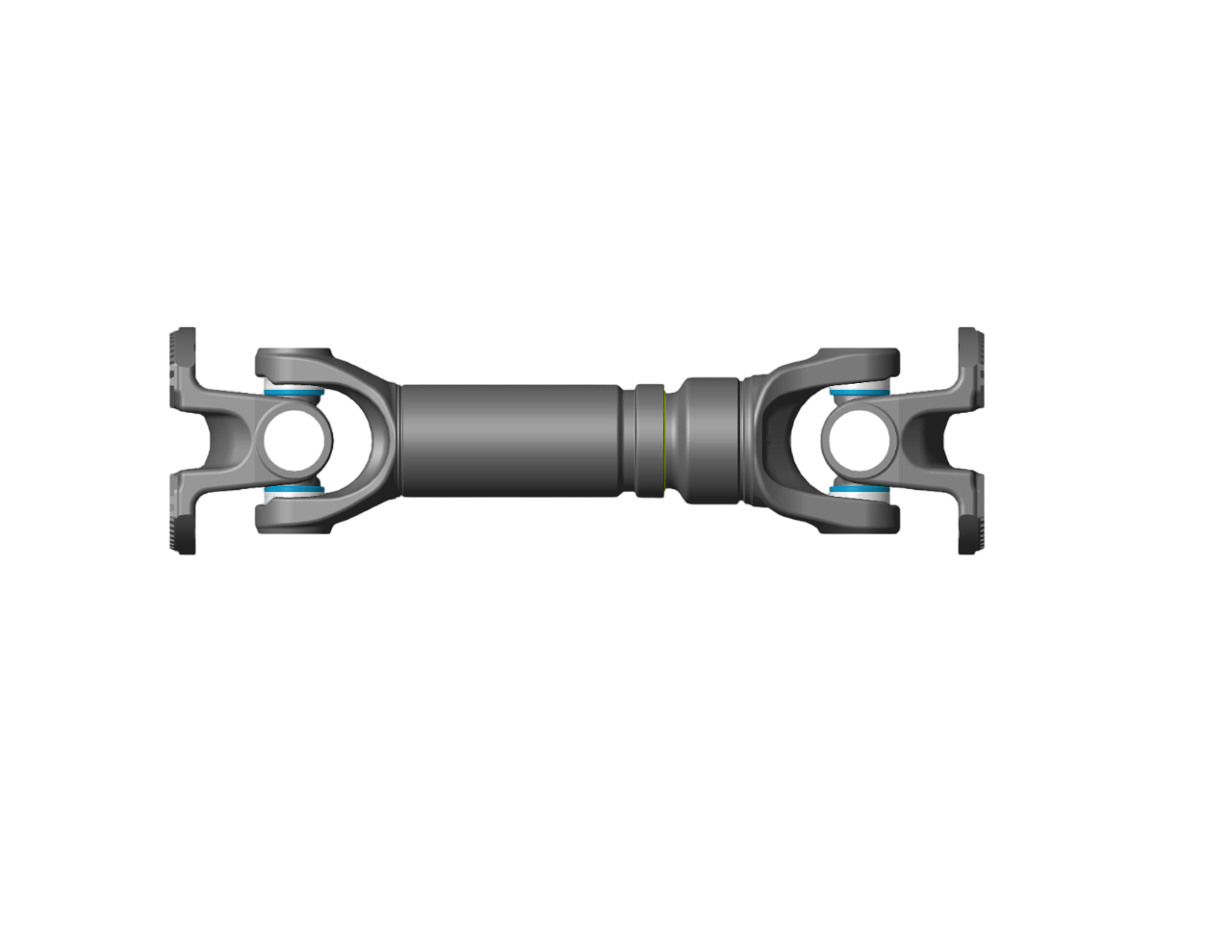

Variant A220

Double joint cardan shaft assembly.

Product Specifications

| Sr No. | RSB Series | Functional Torque (In Nm) | Type of Shaft | Mounting Flange Size | UJ Size (Cup Dia. x Comp. Length) |

Articulation Angle (In Deg.) | Tube Size (OD x Thk.) (In mm) |

Swing Diameter (In mm) |

Slip length (In mm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 066 | 2000 | Out-Board Design | SAE : 4-Holes | 26 x 87 | 22° | 50.8 x 2.4 | 100 | 50 |

| 2 | 099 | 2600 | Unitized Design | SAE : 4-Holes | 26 x 87 | 25° | 63.5 x 1.6 68.9 x 2 |

100 | 50 |

| 3 | 117 | 3500 | Unitized/Conventional Design | SAE : 4-Holes | 30 x 106 | 25° | 68.9 x 2 | 120 | 70 |

| 4 | 123 | 5500 | Unitized/Conventional Design | SAE : 4-Holes & Ø120-X-Serrated | 35 x 104 | 25° | 88.9 x 2.4 | 120 | 70 |

| 5 | 225 | 8000 | Unitized/Conventional Design | SAE : 4-Holes Ø120-X-Serrated | 35 x 126 | 25° | 88.9 x 2.4 90 x 3 |

140 | 80 |

| 6 | 325 | 10,000 | Conventional Design | Ø120-X-Serrated Ø150-X-Serrated |

42 x 120 | 25° | 90 x 3 | 140 | 110 |

| 7 | 325HS | 10,500 | Unitized/ Conventional Design | SAE & Ø120-X-Serrated Ø150-X-Serrated |

42 x 120 | 25° | 100 x 3 | 140 | 110 |

| 8 | 403 | 12,000 | Conventional Design | Ø150-X-Serrated Ø180-X-Serrated |

42 x 129 | 25° & 44° | 101.57 x 3.41 | 150 | 110/140/180 |

| 9 | 490 | 14,000 | Conventional Design | Ø150-X-Serrated Ø180-X-Serrated |

48 x 139 | 25° & 44° | 101.57 x 3.41 100 x 4.5 |

158 / 150 | 110/140/180 |

| 10 | 14K | 14,000 | Conventional Design | Ø150-X-Serrated Ø180-X-Serrated |

48 x 135 | 25° & 44° | 101.57 x 3.41 100 x 4.5 |

158 / 150 | 110/140/180 |

| 11 | 590H | 16,000 | Conventional Design | Ø150-X-Serrated Ø180-X-Serrated |

52 x 147 | 25° & 44° | 103.9 x 4.5 | 172 | 110/140/180 |

| 12 | 590 | 17,000 | Conventional Design | Ø150-X-Serrated Ø180-X-Serrated |

52 x 147 | 25° & 44° | 120 x 4 | 172 / 158 | 110/140/180 |

| 13 | 17k | 17,000 | Conventional Design | Ø150-X-Serrated Ø180-X-Serrated |

52 x 139 | 25° & 44° | 120 x 4 | 172 / 158 | 110/140/180 |

| 14 | 592 | 20,000 | Conventional Design | Ø180-X-Serrated | 57 x 147 | 25° | 120 x 4 | 172 | 110/140 |

| 15 | 620 | 25,000 | Conventional Design | Ø180-X-Serrated | 57 x 152 | 25° | 120 x 6 | 178 | 110/140/180 |

| 16 | 680 | 30,000 | Conventional Design | Ø180-X-Serrated | 57 x 172 | 25° | 140 x 5 180 x 4 |

196 | 110 |

| 17 | 700 | 35,000 | Conventional Design | Ø180-X-Serrated | 65x 172 | 25° | 140 x 5 | 204 | 110 |

| 18 | 710 | 42,500 | Conventional Design | Ø180-X-Serrated | 65 x 172 | 25° | 142 x 6 | 204 | 100 |