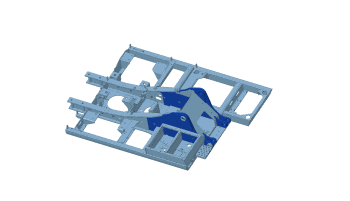

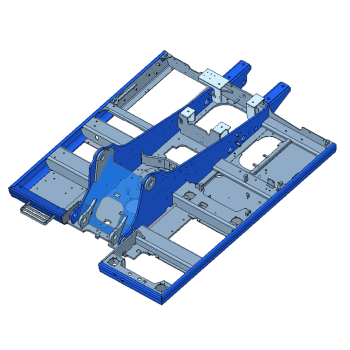

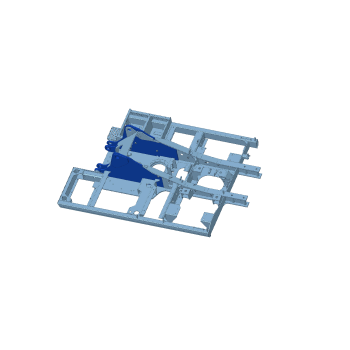

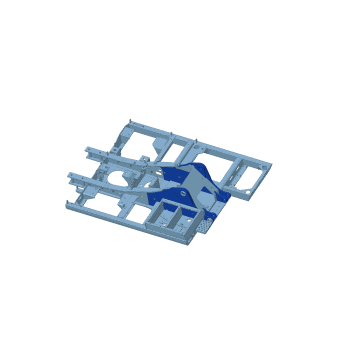

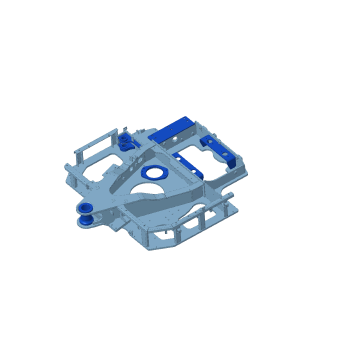

Main Frame

Excavator is a typical structure both in terms of Load transfer from the Attachment to Track Frame and in terms of development and Manufacturing of these structures. Main frame is slender and wide in size. It calls for great care in maintaining dimensional accuracy and distortion control. The in line boring requirements to achieve the concentricity of Bores machined and the precision Flatness requirements in case of Swing bearing mounting area calls for precision machining. RSB has the state-of-the-art CNC machines (5 axis / 7 axis CNC Boring machines and Vertical CNC Boring machines) to cater to these typical precision machining needs. The integration of Centre frame upper, Tail frame along with Side frames in the final stage of manufacture of Mainframe calls for special fixturing and tooling, RSB has perfected the knowhow in these areas in achieving the dimensional accuracy and distortion control. RSB’s main strength lies in scaling up its manufacturing capabilities to cater to the ever-increasing volume requirements of these large structures from the Construction Equipment Manufacturers.

The Main Frames for Mini Excavator and Mining Class calls for extremely different kind of Technology in the development and manufacturing of Mainframes. RSB has the capability to handle these Technology needs of its renowned Construction Equipment Manufacturers.

RSB has capabilities to manufacture of Mainframe which is also called as Upper Frame for the full range of Excavators, (7T,13T,14T,20T & 23T class) since 1998. RSB’s inhouse develop and manufacturing facilities (under one roof) for laser cutting, oxy cutting, plasma cutting, CNC bending, rolling, robotic welding capabilities and CNC machining provides better product integrity.

Product Features

RSB has the capability to Manufacture varieties of Excavator Mainframes. Has over three decades of experience in the manufacture of Excavator Mainframes. Has the capability to manufacture mainframes ranging from Mini Excavator (2 Tonne category) to Mining class Excavator (85 Tonne Class). Has the highly skilled associates who has the knowledge of Welding Quality requirements to Precision Machining. Handled manufacture of Mainframes of leading Construction equipment Manufacturers. RSB’s inhouse develop and manufacturing facilities (under one roof) for, laser cutting oxy cutting, plasma cutting, bending, rolling, robotic welding and machining provides better product integrity with following specification.

Product Variants

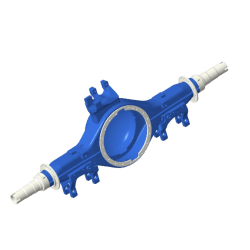

Live Axle Beam/Housing

RSB has developed capabilities to design and manufacturing live axle beam (housing) since 2008. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding, robotic welding and machining provides better product integrity with following specification.

Dummy Axle beam

RSB has capabilities to design and manufacturing live axle beam (housing) since 2004. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding and robotic welding provides better product integrity with following specification. By end of 2022, RSB has sold 1 million axle to India OEMs.

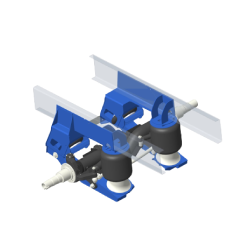

Lift axle Beam

RSB has developed lift axle beam (tubular drop) for dual tyre lift axle for multi axle rigid trucks and haulage tipper application. RSB manufacture the drop tube through cold bending with roller technology (sole manufacturer in India) with controlled CTQ parameters (minimal thinning, ovality, residual stress, straightness). We supply lift axle beam to major OEMs in India.

Steerable Lift axle

RSB Transmission has done strategic alliance (Technical collaboration) with Reyco Granning LLC, USA for primary air suspension & auxiliary (lift) axle for multi axle rigid trucks, tipper, tractor and bus application. Reyco Granning LLC is having 90 years of experience in designing and manufacturing suspension solutions.

12,5T -self steerable lift axle & suspension is a trailing arm type air ride suspension with straight or drop axle for tag / pusher positions for rigid trucks and haulage tipper application.

Product specification

- Upper Frame size (L X W X H) in mm: Range from (2914 X 2204 X 703 To 3818 X 2740 X 740)

- Upper Frame Weight in Kg: Range From 1062Kg To 2020Kg