Rear Axles

Axles are one of the most significant products offered by RSB. It has a staggering capacity to manufacture 3,50,000 Axles/year. There are further plans to enhance the capacity to cater to the export market. Well-equipped manufacturing lines have been dedicated to developing a variety of Axles.

The Rear Axle Beam and Rear Axle assemblies are one of the most significant offerings from RSB. Rear Axle beams for commercial vehicles are manufactured at Jamshedpur and distributed to OEM clients across the country. The product offered starts from sub-2T GVW till 55T GVW capacity vehicles.

RSB is the market leader in manufacturing of Pusher Lift Axle Beams in India, the fully dressed trailer axles designed and developed by RSB finds popular usage among the many of Freight companies for various applications.

State-of-art technology with extensive validation capabilities, RSB Axle manufacturing include facilities for Hot Forming of beams, Robotic Bracket Welding, Friction Welded Spindles, etc.

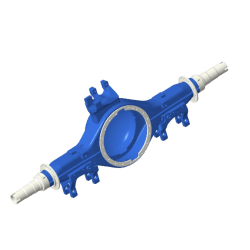

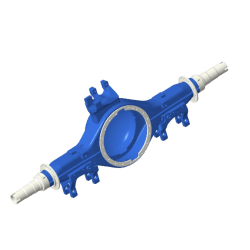

Live Axle Beam Housing

RSB has developed capabilities to design and manufacturing live axle beam (housing) since 2008. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding, robotic welding and machining provides better product integrity with following specification.

Product Features

HCV – Live Axle Tandem

- Track Length: 1814 to 1950 mm

- Vehicle Application: 28T to 55T Rigid trucks/Tipper/Tractor

- Gross Axle Weight Rating: 21-23T

- Beam Thickness: 12 mm to 16mm

- Beam material- High Strength Low Alloy (HSLA) steel upto 620 MPa tensile strength.

- Dome cover: capable to accommodate 490 mm size Crown wheel

HCV -Live Axle Housing (Solo):

- Track Length: 1814-1950 mm

- Vehicle Application: 18T to 55T Rigid trucks/Cargo/Tipper/Tractor

- Gross Axle Weight Rating: 11.5T-15T

- Beam Thickness: 12mm to 14 mm

- Beam material- High Strength Low Alloy (HSLA) steel upto 620 MPa tensile strength.

- Dome cover: capable to accommodate 490 mm size Crown wheel

LCV - Live Axle Housing

- Track Length: 1550 to 1684 mm

- Vehicle Application: 6.5 to 12T GVW Rigid Trucks

- Gross Axle Weight Rating: 3.5 to 5T

- Beam Thickness: 8mm to 12 mm

- Beam material- High Strength Low Alloy (HSLA) steel upto 620 MPa tensile strength

Dummy Axle beam

RSB has capabilities to design and manufacturing live axle beam (housing) since 2004. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding and robotic welding provides better product integrity with following specification. By end of 2022, RSB has sold 1 million axle to India OEMs.

Product Specification

- Track Length: 1814 to 1950 mm

- Vehicle Application: 28 to 49T GVW rigid trucks /tipper

- Gross Axle Weight Rating: 10 to 16T

- Thickness: 12mm to 16mm

- Beam material- High Strength Low Alloy (HSLA) steel upto 620 MPa tensile strength

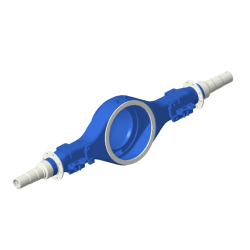

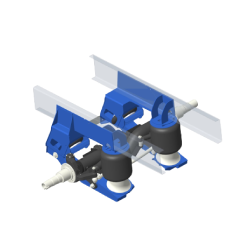

Lift Axle Beam

RSB has developed lift axle beam (tubular drop) for dual tyre lift axle for multi axle rigid trucks and haulage tipper application. RSB manufacture the drop tube through cold bending with roller technology (sole manufacturer in India) with controlled CTQ parameters (minimal thinning, ovality, residual stress, straightness). We supply lift axle beam to major OEMs in India.

Product Specification

- Gross Axle Weight Rating (GAWR) : 12,500 Kg

- Tube diameter range from 127 (5”) to 146 (5.75”) mm with thickness 14 -23 mm

- Capable to bend tube with center drop from 127 (5”)- 150 (6”) mm

- Tube material strength upto 750 MPa.

- Robotic welding of axle saddle

- Friction welded induction hardened spindle

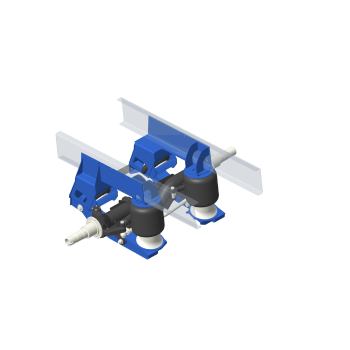

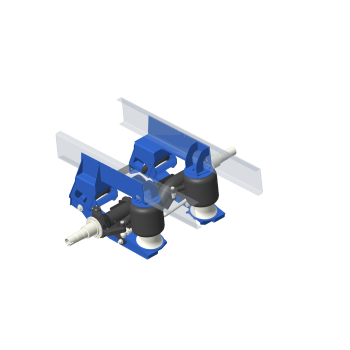

Steerable Lift Axle

RSB Transmission has done strategic alliance (Technical collaboration) with Reyco Granning LLC, USA for primary air suspension & auxiliary (lift) axle for multi axle rigid trucks, tipper, tractor and bus application. Reyco Granning LLC is having 90 years of experience in designing and manufacturing suspension solutions

12,5T -self steerable lift axle & suspension is a trailing arm type air ride suspension with straight or drop axle for tag / pusher positions for rigid trucks and haulage tipper application.

Product Specification

- Gross Axle Weight Rating (GAWR): 12,500 Kg

- Pusher/tag application

- Tubular lift axle & trailing arm style air suspension for rigid trucks & haulage tipper application.

- Total axle travel : 225-250 mm

- High strength low alloy axle tube with 125-150 mm drop.

- Adjustable wheel track and chassis width

Product Features

- U- Bolt free design (improved axle life eliminating torsional load in cross twist)

- Reduce axle assembly time (tightening of 4 bolts instead of 8 U -bolts)

- Leading king pin : Steer angle : 14 deg (could be adjusted)

- High pressure mono tube, self-centring shocks

- Serviceable dual draw key king pin housing

- Positive dampening to prevent shimmying during highway speed operation.

- Lock straight mechanism to keep wheels straight while axle lifted in unladen / reverse condition.

- Auto lifting during sharp turning

- Tire life increase by ~15-20% (compare to non steer application)

- Driver fatigue reduced for ease of maneuverability.

Product Variants

Live Axle Beam/Housing

RSB has developed capabilities to design and manufacturing live axle beam (housing) since 2008. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding, robotic welding and machining provides better product integrity with following specification.

Dummy Axle beam

RSB has capabilities to design and manufacturing live axle beam (housing) since 2004. RSB’s inhouse design and manufacturing facilities (under one roof) for cold/hot forming, friction welding and robotic welding provides better product integrity with following specification. By end of 2022, RSB has sold 1 million axle to India OEMs.

Lift axle Beam

RSB has developed lift axle beam (tubular drop) for dual tyre lift axle for multi axle rigid trucks and haulage tipper application. RSB manufacture the drop tube through cold bending with roller technology (sole manufacturer in India) with controlled CTQ parameters (minimal thinning, ovality, residual stress, straightness). We supply lift axle beam to major OEMs in India.

Steerable Lift axle

RSB Transmission has done strategic alliance (Technical collaboration) with Reyco Granning LLC, USA for primary air suspension & auxiliary (lift) axle for multi axle rigid trucks, tipper, tractor and bus application. Reyco Granning LLC is having 90 years of experience in designing and manufacturing suspension solutions.

12,5T -self steerable lift axle & suspension is a trailing arm type air ride suspension with straight or drop axle for tag / pusher positions for rigid trucks and haulage tipper application.

Steerable Lift Axle

Product Features- U- Bolt free design (improved axle life eliminating torsional load in cross twist)

- Reduce axle assembly time (tightening of 4 bolts instead of 8 U -bolts)

- Leading king pin: Steer angle: 14 deg (could be adjusted)

- High pressure mono tube, self-centring shocks

- Serviceable dual draw key king pin housing

- Positive dampening to prevent shimmying during highway speed operation.

- Lock straight mechanism to keep wheels straight while axle lifted in unladen / reverse condition.

- Auto lifting during sharp turning

- Tire life increase by ~15-20% (compare to non-steer application)

- Driver fatigue reduced for ease of maneuverability.